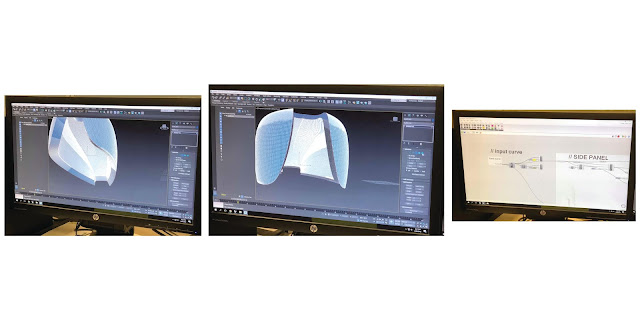

ASSIGNMENT 3 1. FINISHES The bowl, tray, torus and blister were all finished in form to a sound level however the finishes of said four pieces were underwhelming. I attempted to sand the toros but eventually gave up. I was unaware at this stage of the ability of the sandpaper to be exceedingly more useful when wet and so I had only attempted a single grit, dry paper to sand the aluminium, resulting in uneven surfaces. The finish of project two, the motorbike tank, can be contrasted to that of my first projects in regards to finish as I spent a substantial amount of time sanding this with three different grits of sandpaper and also used the sandpaper wet to enhance the outcome. This can be seen in the following photos that show an advancement in the finishes of project 1 to project 2. 2. RELATIVE TO INTERIOR ARCHITECTURE The skills that I was able to obtain during the Digital Making 0014 course were extensive. The ability to learn how to form and mould metal into objec...